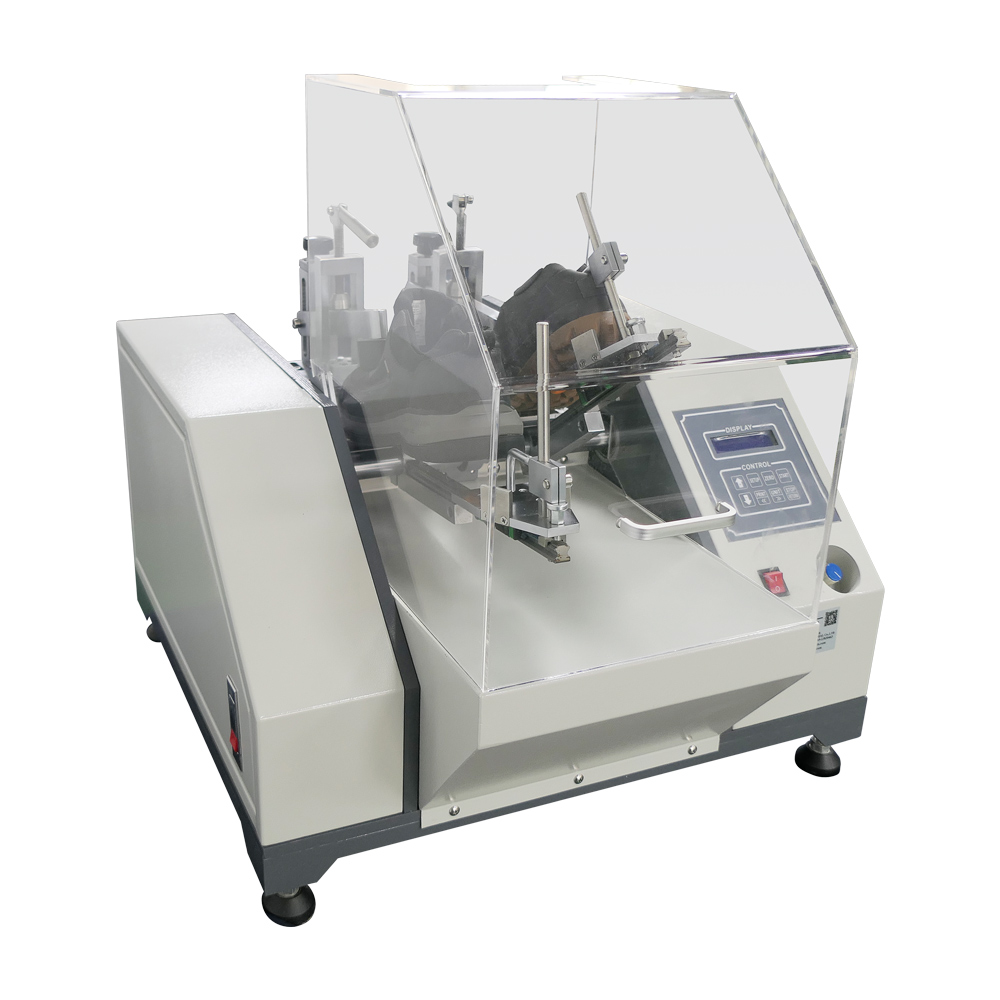

SK-688 3D Upper Moulding Machine

Parameters of 3D Upper Moulding Machine:

|

Machine

Dimension |

L 840 * W 960 *H 1600mm |

|

Weight |

467KG |

|

Voltage |

220V

50HZ |

|

Power |

2.2KW |

|

Air

source |

0.6MPa |

|

Output |

1000-1200

pieces/day |

|

Model |

SK-688 |

Features of 3D Upper Moulding Machine:

1) The 3D upper shaping machine is a kind of machine

that uses high temperatures to melt the hot fuse in the upper fabric, so that the fabric is hardened, which is convenient for workers to cut and shape.

First, after the upper cloth is processed, it needs to be heated to melt the hot fuse in the upper cloth, and the temperature should

not be too high or too low. After heating, pressurize and cool again to achieve the effect of not rebounding after

setting.

2) This machine integrates three major functions in one, at the same time, the

upper of the seam is shaped, warped, and ironed at the same time so that the upper and the last are perfectly fit.

3) After shaping, there is no need for secondary trimming.

4) After shaping, the upper will not be deformed.

5) The versatile stereotypes are suitable for all kinds of men, women, and

children's shoe uppers.

6) The machine is easy to adjust and the upper shape is easy.

7) The upper is easy to place without clamping jaws.

8) The shaping effect is perfect, and the shaping takes a short time to

effectively increase production capacity.

9) This machine is suitable for uppers, riding boots, sheet materials, and

sandals that have been sewn.

What is 3D injection molding?

3D printing technology is an additive printing process that creates objects by building layers of material, while plastic injection molding uses a mold that is filled with molten material that cools and hardens to produce parts.

- [email protected]

- skylineinstruments

- +86 13751491529

- +86 13751491529

+86 13751491529

+86 13751491529 +86 13751491529

+86 13751491529